Auto Roll Welded Wire Mesh Machine For Mining

Basic Info

Model No.: JIAKE DNW

Product Description

Auto Roll Welded Wire Mesh Machine For Mining

This machine makes mesh used to make construction mesh, wall mesh, animal

cage, mining etc.

Machine Description

1 The longitude wire and cross wire are fed from wire coils automatically. Longitude

wire :Wire rolling machine+Bobbin stand-off with rollers (0.65-1.2mm) Iron wire pay-off (1-2.5mm).Cross wire:wire pay-off

2 The cross wire are pre-straightened &pre-cut.

3 The middle knife can cut the mesh into 2 mesh if width enough.The side knife will

cut the extra cross wire out of side.

4 The thorn shaft(above big shaft) is to fix the mesh.

5 The little shaft is to keep the tensity of mesh.

6 In front of machine on the right is control cabinet.It can adjust speed.

7There are transformer,motor,reducer on the backside of machine.

8 The raw material can be low-carbon steel wire (black wire) and galvanized wire.

9 We will use Schneider electric components, Delta inverter in the electric control cabinet.

We will use the best quality main motor&reducer, it will be equipped with inverter.

10 The middle cutter and sider cutters can be adjusted randomly to make two mesh rolls at same time.The mesh roll length can be set by counter switch on the control panel.

11 The welding transformers have 8 degrees and can be adjusted for different wire

diameters.The welding time and welding current can be adjusted on the control panel

to adjust the welding degree.

Advantage

1 easy operated

2 high production

3 advanced technology electronics.

4.Separate control technology, make welding transformers working separately to

reduce needed capacity.

5.Different position of button and control box with inverter (Taiwan Delta), not easily broken like before, easier to operate.

6.Sealed welding transformers, it has 8 degrees, can be adjusted for different wire diameters.

7.Square steel bottom instead of angle iron bottom. 1.5mm steel plate instead of

0.2-0.3mm steel plate, more stable.

Technical parameter

Type | DP-DNW-1 | DP-DNW-2 | DP-DNW-3 |

Wire diameter | 0.4-0.65mm | 0.65-1.8mm/0.8-2mm/0.65-2mm | 1.0-2.2mm/1.2-2.5mm |

Aperture/pitch | 1/4", 1/2" 6.25, 12.5mm | 1/2", 1", 2", 3", 4" 12.5, 25, 50mm | 1", 2", 3", 4" 25, 50, 75, 100mm |

Mesh width | Max.1m, 1.2m | Max.1.2m,1.5m, 2m | Max.1.2m, 1.5m, 2m, 2.5m |

Motor | 2.2kw | 2.2kw; 4kw | 4kw; 5.5kw, 7.5kw |

Welding speed | Max.75 rows/min | Max.120-180 rows/min | Max.80-120 rows/min |

Transformer | 50kva*3 | 60kva*4;60kva*5, 60kva*7 | 70kva/80kva*5/6/7/8 |

Weight | 1.5T | 2T, 2.5T | 2T, 2.5T, 3T, 3.5T |

Detailed Information

Auxiliary Equipment

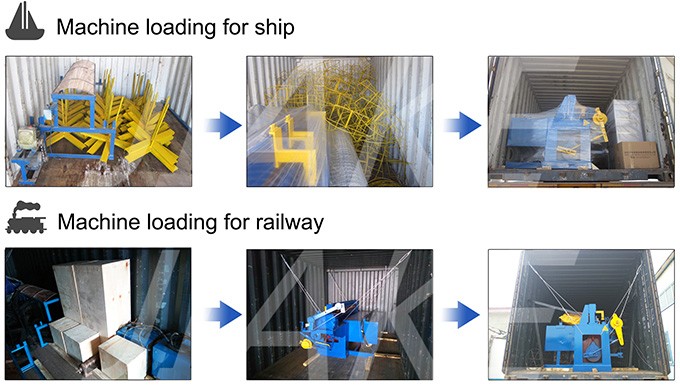

Load

Certificate

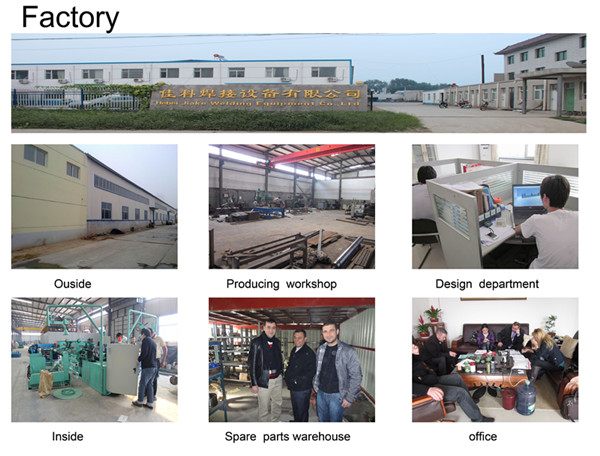

Factory

Hebei Jiake Welding Co ltd have an experience on designing and manufacturing wire

mesh machine for more than 10 years.Our welded wire mesh machines have exported to

more than 90 countries.Welcome to visit our factory and have more deeply cooperation..

Service

Contact us

Contact us if you need more details on Welded Mesh Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Roll Welded Wire Mesh Machine、Auto Roll Welded Wire Mesh Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Roll Mesh Welding Machine > 0.4-2.5mm Roll Mesh Welding Machine

Premium Related Products